Plastic, Acrylic Glass, or Plexiglass is a remarkably popular material in industrial and domestic use because it is transparent, flexible and strong. The need for custom size plexiglass in various sizes with respect to DIY activities, home fittings, signage and industrial applications keeps on expanding. However, what does the term custom size include and why it is necessary?

This comprehensive article explains all you need to know about custom-size plexiglass, the possible thicknesses and how you can customize it, how to use it in your application and things to consider before ordering it.

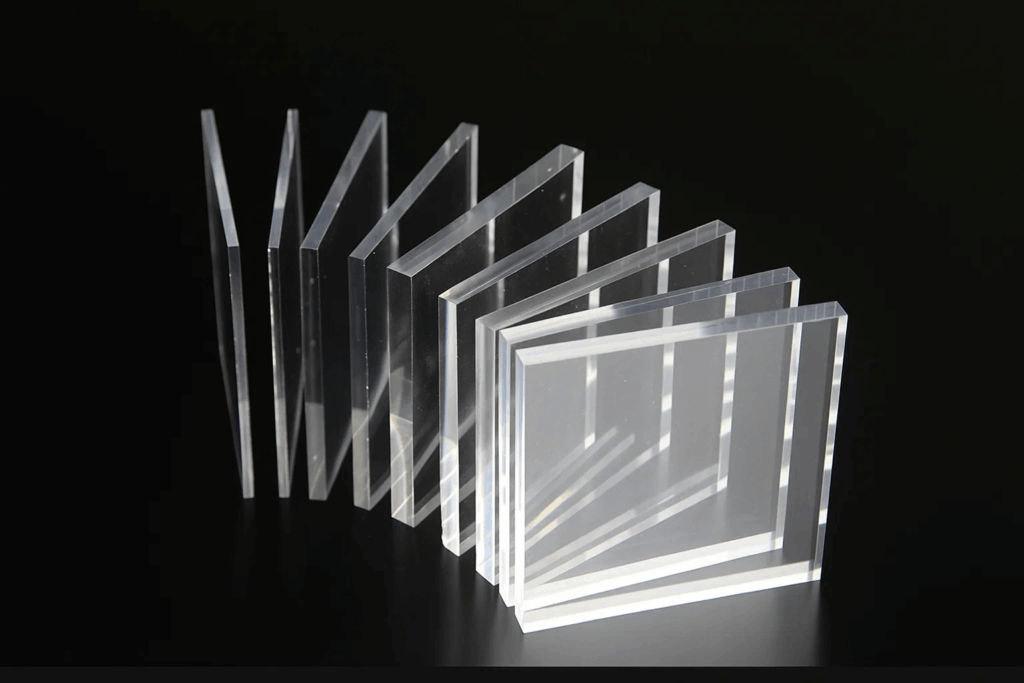

What Is Plexiglass and Why Custom Sizing Matters?

Acrylic is a transparent thermoplastic that is commonly used as lightweight, shatterproof substitute of glass. It is called polymethyl methacrylate (PMMA) in technical terms.

There are standard sheet sizes (usually 4×8 feet), but in most projects, the size may be required to fit the size of the project. When installing a protection barrier, the display case or the windowpane, cut-to-size plexiglass will make it fit perfectly and look professional. The customized approach also limits wastage, trimming time, and increases the quality of the design as a whole.

Popular Applications for Custom Size Plexiglass

It is not only custom plexiglass sizing that serves an aesthetic purpose, but functionality as well. And this is where customized dimensions count:

1. Windows and Glazing

Among the regular domestic homeowners, plexiglass-based windows are used instead of conventional glass because of its durability. It is good for shed windows, or basement enclosures or even storm window inserts.

2. Protective Barriers

Critically after the pandemic, retailers, offices, and healthcare facilities are using clear acrylic panels that can help them stay hygienic and safe and still keep the visibility.

3. Picture Framing

Through custom acrylic sheet, photographers and artists substitute glass in the frame to give it more strength in the course of transportation, and in the case of gallery installations.

4. DIY Furniture & Decor

The customizable design of plexiglass allows the fabrication of non-standard furniture and home décor to furniture tops and shelving, and wall art.

5. Signage and Displays

Plexiglass sheets can be especially used to make storefront signs, menu boards, holding brochures, and display cases at the museum as they can be printed on and are quite clear.

Types of Plexiglass Based on Finish and Color

The selection of the custom size plexiglass is not the only thing involved. It is also vital to know the kind of diverse finishes available:

1. Clear Plexiglass

Best for applications requiring maximum visibility, such as windows, sneeze guards, and display panels.

2. Frosted or Matte Finish

Ideal for privacy screens or artistic installations that need light diffusion without transparency.

3. Colored and Tinted Sheets

Useful for branding, decorative purposes, or UV filtering (e.g., smoked plexiglass panels).

4. Mirrored Plexiglass

A lightweight alternative to traditional mirrors, great for RVs, gyms, and decorative installations.

Thickness Options – How to Choose the Right One

Choosing the right thickness of your custom cut plexiglass is probably one of the most important steps of ordering it. The simplest way to distinguish them is like this:

| Thickness | Common Use Cases |

| 1/8” (3mm) | Light-duty projects like signs and picture frames |

| 3/16” (4.5mm) | Window panes, retail displays |

| 1/4” (6mm) | Shelving, sneeze guards, protective barriers |

| 3/8” to 1” | Heavy-duty uses like furniture tops and aquariums |

A supplier or installer plexiglass thickness guide should be used when in doubt to help select the right thickness suited to safety, and performance.

Customization Options: More Than Just Size

1. Drilling & Hole Placement

Pre-drilled holes may save time on some mounted applications or where hardware is to be attached and cracking caused by the drill penetrating incorrectly.

2. Polished Edges

Beautiful on decorative work, particularly where the edges are to be seen, such as in show-cases or advertisement work.

3. Rounded Corners

Safest in busy areas or in children’s areas. These can be in many cases rounded corners on tabletop plexiglass protectors or wall mounted sheets.

4. UV-Resistant Coatings

Best for outdoor installations. The anti-UV plexiglass will ensure that it will not turn yellow and decay with time.

5. Anti-Glare Finishes

Just right in signs or digital screens that are in an environment that poses some form of reflection.

Benefits of Custom Size Plexiglass Over Standard Glass

1. Shatter Resistance

Unlike glass, plexiglass won’t shatter into dangerous shards. This makes it safer for homes, schools, and commercial environments.

2. Lightweight

Custom acrylic panels are significantly lighter than glass, making them easier to transport and install, especially in large formats.

3. High Clarity

Premium optical-grade plexiglass can rival glass in transparency while offering greater durability.

4. Weather Resistance

Well-suited for outdoor use, plexiglass can withstand UV exposure, wind, and rain, especially when treated with the right coating.

5. Cost-Effectiveness

While not always cheaper than glass, the long-term savings from lower replacement and maintenance costs are considerable.

How Custom Size Plexiglass Is Measured and Cut

When ordering, it’s crucial to understand how measurements work. Most vendors require dimensions in inches or millimeters and will cut using CNC routers or laser cutters for precise sizing.

Tips for Accurate Measurement:

- Always use a metal tape measure for consistency.

- Account for fitting space (i.e., allow slight clearance in window or frame applications).

- For inserts or replacements, measure both width and height in at least three points to identify inconsistencies.

Environmental and Safety Considerations

Recyclability

Plexiglass is recyclable (type #7 plastic), though not through typical curbside programs. Specialized facilities can reprocess it into new materials.

Indoor Air Quality

Modern plexiglass is low-VOC and generally safe for indoor use. Still, proper ventilation is recommended during cutting or sanding to avoid inhaling dust.

When to Choose Custom Size Plexiglass vs. Standard Sheets

Standard sheets may suffice for temporary or general-purpose applications. However, custom sizing is invaluable when:

- You need a perfect fit (e.g., glazing replacements or signage).

- You want to avoid waste or resizing.

- Aesthetic or design precision is critical.

Final Thoughts

By selecting custom size plexiglass, any homeowner who wants to spruce up his or her home, a showcase designer, or a business developing protective solutions can start a world of possibilities. Regardless of whether you want your acrylic sheets to be covered in UV coating or polished edges, material thickness and finishing add different weights to your material, but increase longevity and control how it looks and performs. Custom plexiglass has become an economical, intelligent option to supplement business and hobby needs as the need to acquire safe, flexible and attractive materials rises.