In the sprawling e-commerce landscape, the priority to swiftly and proficiently deliver products has surged in significance, this pressure for speed has spurred the development and polishing of complex logistics strategies, prominently multi-warehouse fulfillment systems. The goals of such a system include reducing both shipping times and costs, improving inventory management, and ultimately, better customer satisfaction. This article considers how multi-warehouse fulfillment networks have transformed the logistics environment for an enterprise to meet the rising demand from a worldwide market.

1. Multi-Warehouse Strategy: A Game Changer in Logistics

The Shift to Decentralization

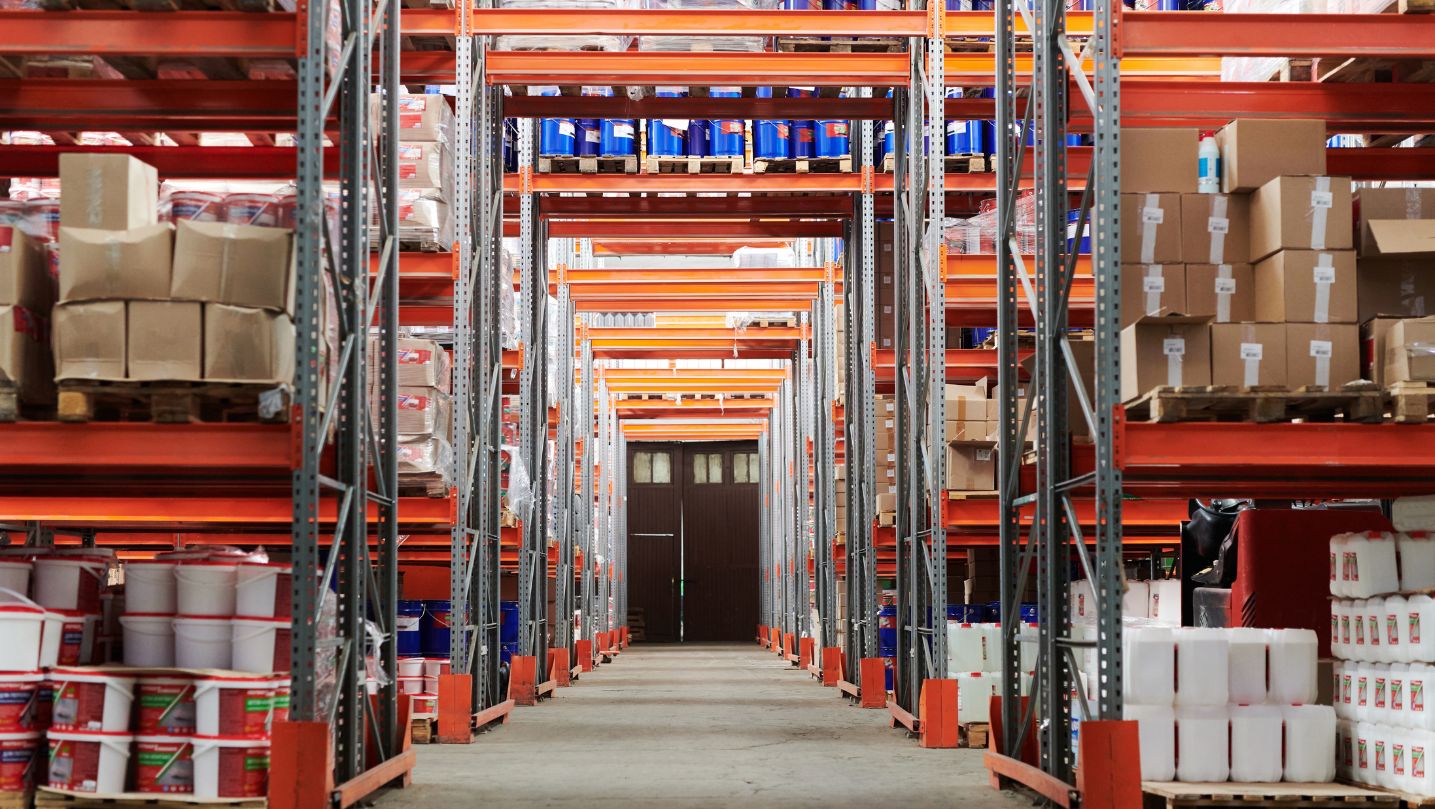

The single, central warehouse model is giving way very rapidly to a more dynamic, flexible approach. Companies are using more multi-warehouse fulfillment as a mean of decentralizing inventory, this change in strategy enables a company to position its products closer to key markets, significantly cutting delivery times and transportation costs. Concentrating inventory across multiple locations aids the company in controlling stock levels more effectively, thereby curtailing the risk of supply chain disruptions.

Leveraging a Robust Fulfillment Network

The key to any successful multi-warehouse strategy is the creation of a strong fulfillment network through strategically located physical warehouses, managed through sophisticated logistics software, and capable of maintaining updated stock in several locations. In such a fulfillment network, inventory is always prepared to move at the speed of demand, which gives one the fighting chance in the market that prizes speed and reliability so highly. Working with the leading fulfillment companies can help optimize this network, ensuring inventory is always prepared to move at the speed of demand. This gives businesses a fighting chance in a market that prizes speed and reliability so highly.

2. Technological Innovations Driving Efficiency

Integration of Advanced Software Solutions

The foundation of every successful multi-warehouse strategy is technology, technologies knit together operations across different warehouses, from systems that manage inventories to sophisticated routing algorithms.

These tools supply real-time data on inventory levels, order status, and timelines for delivery, enabling precise coordination and efficiency throughout the fulfillment network.

AI and Machine Learning Enhancements

AI and machine learning further fine-tune the power of multi-warehouse systems. AI predicts order trends and adjusts inventory distribution accordingly, while machine learning algorithms work out the most efficient shipping routes and methods. The result of all that is not only a guarantee of speedier delivery times but also reduced waste and increased sustainability in operations.

3. Benefits and Challenges of Multi-Warehouse Fulfillment

Expanded Reach and Reduced Costs

The major advantage that a multi-warehouse system extends is enlarged geographical coverage, and locating warehouses in different regions actually provides a business with an opportunity to serve more customers with efficiency. Further, sending merchandise from a warehouse closer to the customer’s location decreases the shipment time and cost in a major way.

Equally, there are many challenges in operating a multi-warehouse system. The problem of coordinating inventories and logistics at multiple points requires the same high level of operational oversight.

Management of overstocking, understocking, and delays in logistics needs to be so detailed to avoid impacts on customer experience.

Conclusion: Adapting to a Dynamic Fulfillment Landscape

Such emergence and further development of multi-warehouse fulfillment strategies are the signs of the changing global market demands. Companies that will be able to flexibly meet such changes with the emergence of technologically advanced fulfillment networks will be guaranteed increased operational efficiency, customer satisfaction, and a leading position in the world of e-commerce. In their further development, these strategies will surely make their contribution to the future of logistics and SCM.