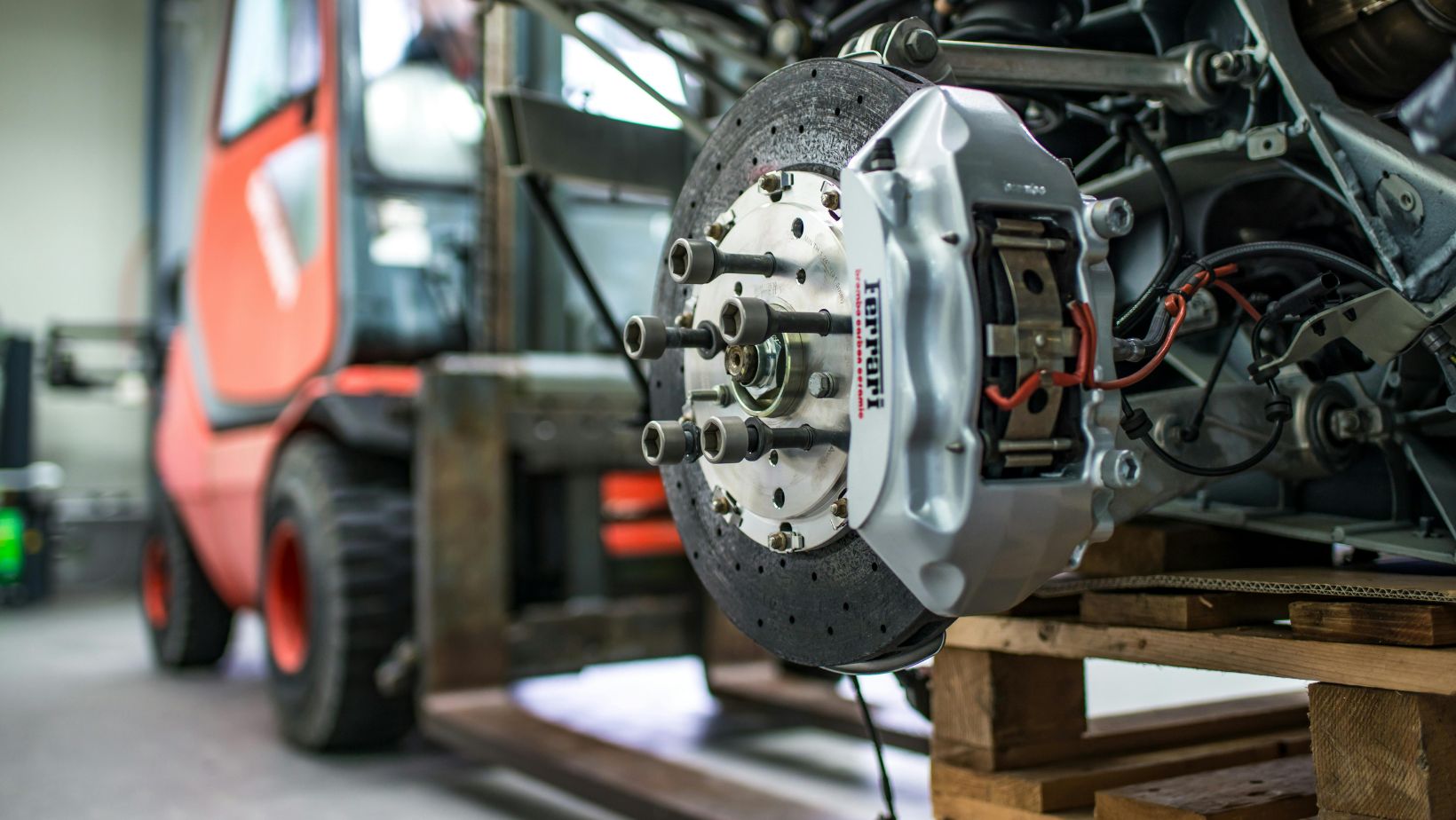

Imagine that you are a customer looking to hire someone to do some work on your car. You pull into a mechanic’s garage and are confronted by a mess. Tools are scattered all over the floor and on every flat surface. Oily rags are piled in a corner and papers are blowing across the grease-stained concrete floor. But in a second mechanic’s garage, you see the opposite. The garage is in pristine condition. Tools are clean and carefully stored in toolboxes, tool chests, and wall storage fixtures. There are designated receptacles for used supplies, and the floor has recently been mopped.

Which of these two garages would you trust to work on your car?

A well-organized tool system helps to promote a clean, efficient, and professional workspace that creates a positive impression on customers, conveys trustworthiness, and promotes greater productivity.

In this article, we’ll take a look at the power of a well-organized tool system to maximize workshop efficiency so you can make an informed decision about how to best promote effective tool storage.

Faster Access to Tools

Speed is an important factor in measuring workshop efficiency, and a well-organized tool system helps to speed up workflow.

With a well-organized system, workers have faster access to the tools they need when they need them because they know exactly where they are and can find them quickly and easily. Because workers will spend less time searching for the tools they need, task execution efficiency is maximized. If you also color-code your tools with a clear labeling system, you can increase speed still more by ensuring that workers can find the right tool within the storage system even more quickly while reducing the risk of errors caused by selecting the wrong tool or misplacing a tool.

Improved Workshop Safety

Workplace accidents are a major concern. In the UK, 600,000 people are injured in the workplace each year with more than 130 killed, while in the United States, there are 2.6 million annual workplace injuries and more than 5,000 annual fatalities.

As a business owner, you want to do everything you can to limit or eliminate workplace injuries. Proper tool storage through a well-organized tool system can help reduce the occurrence of accidents in your workplace. When tools are organized logically and stored properly with kaizen foam, there is less of a risk of accidents occurring. For instance, you should store sharp tools in areas where they are secure and workers are less likely to be looking for them while distracted.

Similarly, as part of your organizational system, you should institute regular maintenance checks to ensure that tools are in their proper location and are in good working order. That way, damaged or malfunctioning tools can be quickly spotted and replaced before an injury occurs.

Improved Productivity

Tool storage isn’t just about keeping your tools safe and secure; it’s also about creating a system that allows workers to maximize their efficiency when using them.

For example, when tools are organized according to the order in which they will be used, employees can move seamlessly from one task to the next, thus making for a smoother and more efficient workflow. Another way to organize tools for efficiency is to group them by the type of task they are used for so that specialized workers have immediate access to specialized tools for their particular task.

For projects that require specialization, this can be an important way to improve logistics and efficiency. When workers have access to the tools they need and don’t need to compete with other workers for those tools, it speeds up task completion.

Better Use of Work Spaces

A well-designed tool storage system also makes the workplace more effective at a physical level. Optimized storage solutions help to store more tools in less space and give you the ability to position tools where they will be needed. Doing so frees up space in the workshop, allowing workers to move around more easily and providing additional space for work-related tasks or for inventory storage.

When storage is designed with the company’s workflow and particular needs in mind, it can help you to transform your location into an efficient and effective workspace.

Easier Cleanup

Finally, well-designed tool storage systems also make it easier to put tools away at the end of the workday. When everything has a specific place, everyone knows where to return tools at the end of the day, keeping the workplace free from clutter and ensuring it is ready for the next work day.